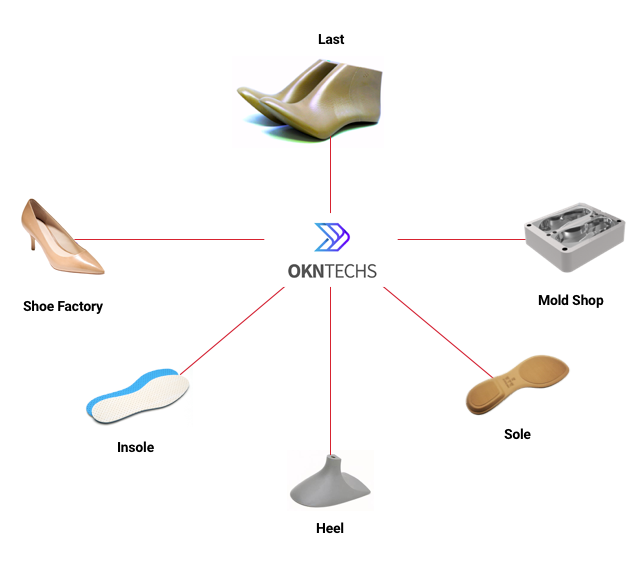

SOFTWARE CAD 3D OKN FTW

With OKN FTW, the development process becomes completely virtual and triggered simultaneously, as shown in the graphic. In this development model, all processes are triggered after shoe last file is built, uppers, insoles, heels, soles and wedges are developed at the same time, resulting in a great time reduction for the shoe model approval and optimization of the entire process.

Shoe Last Module

Create, transform, grade and export your shoe lasts virtually, with mechanical precision and ease.

Sole

Functions that help the development and especially the adjustment of the soles so that they perfectly match the shoe last and upper.

2D and 3D Grading

At the same points and with the same shape rules, making it possible to coordinate parts of the sole.

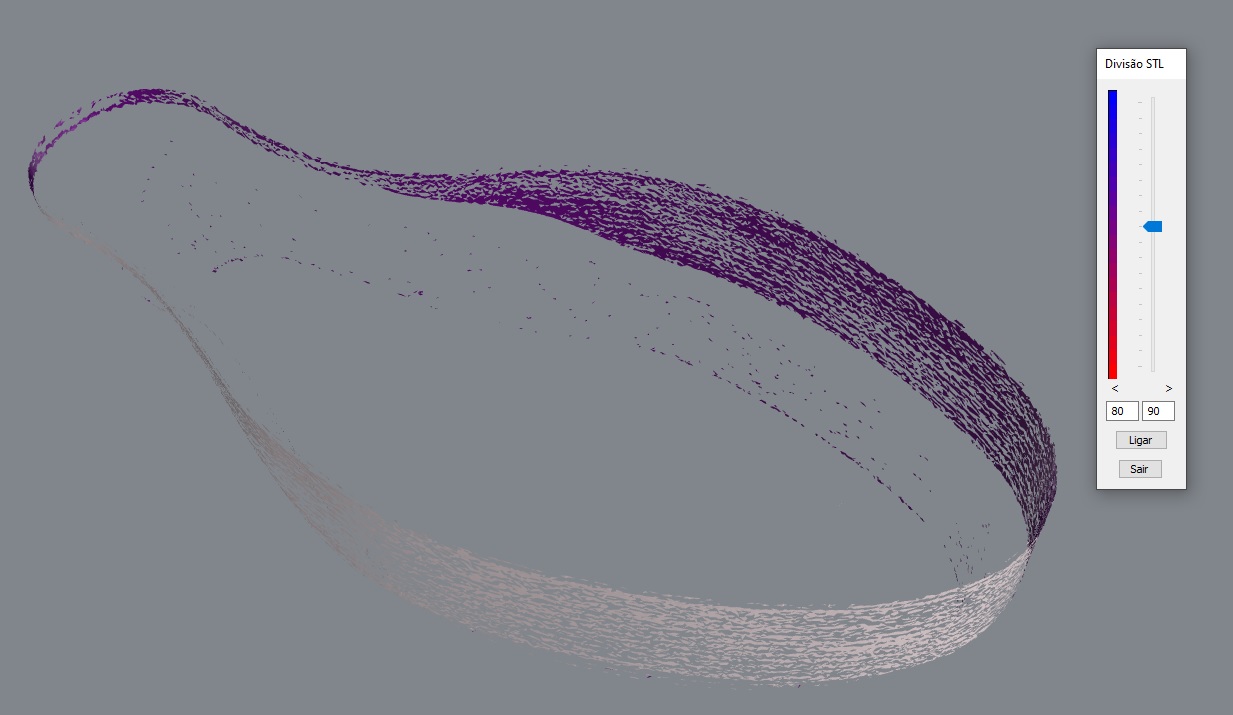

Vectorization

Transforming images based on pixel grids, also known as raster images (ex. bitmap, jpg) into shape-based images (circles, dots, lines…) mapped onto the X, Y and Z Cartesian planes.

Alignment

Precise and automatic alignment of two objects automatically, making it easy to compare and measure differences, for example, or enabling the machining of a mold cap on a casted base.

Automatic transformations

I. Contour II. Curvature and height changes III. Profile change IV. Thickness changes

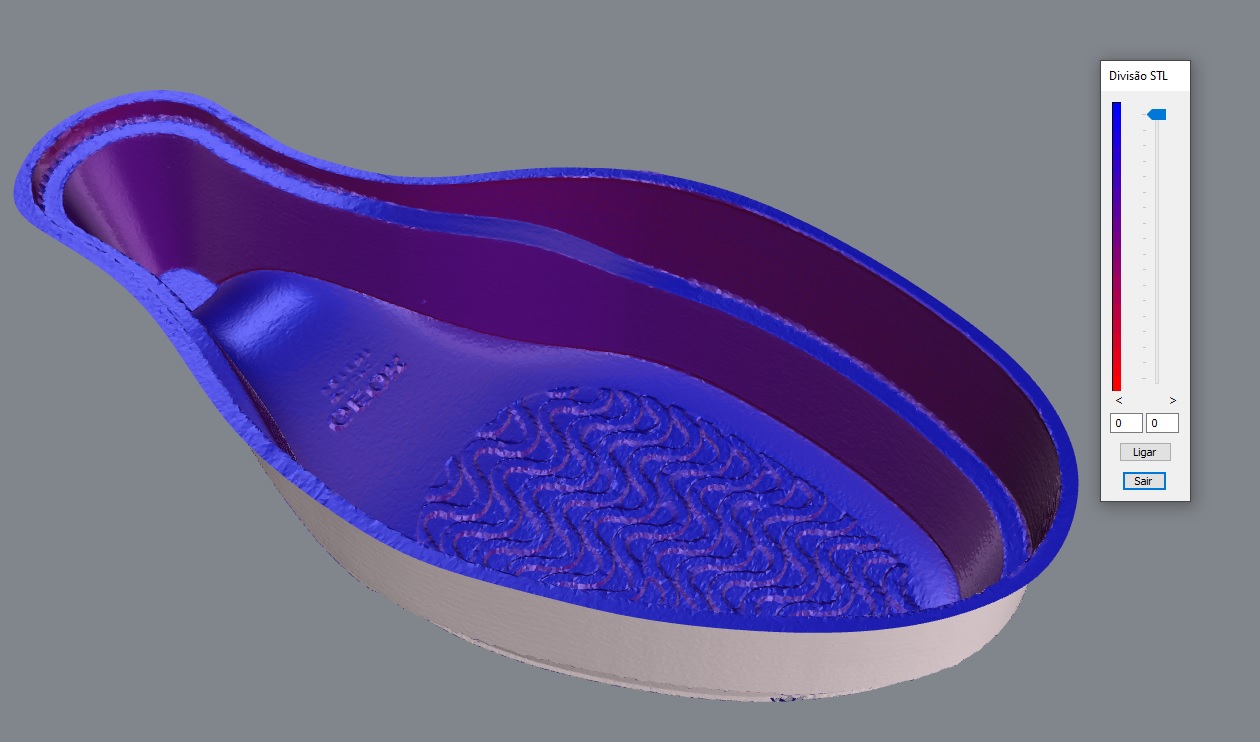

Insole

Features build for the development of structural, anatomical and injected insoles for shoes or sandals. The insole is created directly under the virtual shoe last bottom for a perfect fit. Module main functions.

Creating an insole

Creation of a virtual insole based on user-defined curvatures, angles and thicknesses.

Insole Grading

Insole grading allowing you to control the thickness in each number.